Calibration of medical measuring devices

Blood pressure meters

Analog, digital, or mercury-based blood pressure meters can be used to measure blood pressure. All meters must be inspected regularly in accordance with the national legislation related to blood pressure meters verification procedures (in Slovenia Pravilnik o postopku redne overitve merilnikov krvnega tlaka). At SIQ, we perform periodic inspection of blood pressure meters by finding the blood pressure meter in the database containing all approved types. Alternatively, we can also include a new type of meter into the database if it holds an approval certificate. Compliant pressure meter is marked with a distinctive green label containing validity date, which proves compliance with prescribed legislation requirements. International recommendation OIML R 16 and OIML R 16-2 are used as reference. In addition to inspection, SIQ can also calibrate blood pressure meters; the calibration parameters depend on meter type, but the following parameters are generally calibrated:

- accuracy of the meter for ascending and descending values

- hysteresis error if the meter has this function

- other functional tests (g., sealing of the pneumatic system, rapid pressure release test according to specified requirements)

The accompanying cuff needs to be delivered with the meter for a comprehensive inspection of the meter. We also inspect the mercury decline, test the mechanism used for placing the meter, and check the quality of mercury (whether it is free of air bubbles) for the mercury-based blood pressure meters.

Personal and laboratory scales

Scale is a meter that measure body weight based on the gravity effect. The first scales were developed by Indian civilizations around 2400 to 1800 BC. To date, scales have become a sophisticated and indispensable tool in both professional and personal use. Moreover, a legal metrology precisely prescribes the purpose, accuracy, and other using conditions for different types of scales.

A variety of scales with different ranges exists nowadays. Accurate scales in medicine are prerequisite for correct diagnosis of patients and crucial for ensuring appropriate composition of drugs in pharmacy. On contrary, improperly inspected, or uncalibrated scales can have multiple detrimental effects for human health (e.g., inadequate doses of drugs, incorrect diagnoses due to scale malfunction or due to incorrect mass of the patients).

At SIQ we calibrate electronic, electromechanical, and personal scales. Additionally, we also inspect the scales according to regulations (in Slovenia Pravilnik o meroslovnih zadevah za ne-avtomatske tehtnice). After pre-temperature stabilization and pre-loading, the following parameters are usually inspected/calibrated:

- repeatability which is a difference between the maximum and minimum read value for a given number of measurements

- accuracy and linearity for increasing and decreasing loads

- TARA for increasing and decreasing loads if available

- eccentricity, which is the difference between the maximum and minimum readings relative to the reference center position

Accredited calibrations of scales are performed in the laboratory or at the customer’s premises in the range from 50 g to 280 kg.

Thermometers

The temperature meters show the temperature for selected thermocouple type by recalculating DC voltage that is measured at the input terminals of the meter. We perform accredited calibration for all types of measuring instruments and for all thermocouple types (i.e., B, E, J, K, N, R, S, T, C, A, U). We can also provide accredited calibrations of temperature sensors in cooperation with external partners. More about temperature calibration can be found at the Temperature web site.

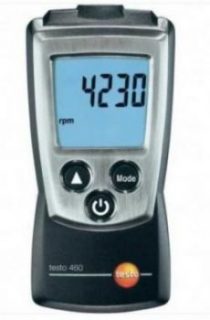

Speedometers

Speedometers are used in pharmaceutical production as well as for other process monitoring where rotation speeds or operating frequencies are important (e.g., mixing, turning, rotating, etc.). We distinguish optical, inductive, electronic, and acoustic meters. During the calibration we check the following parameters:

- frequency

- period

- duty cycle

- rotation speed (accredited calibration in the range from 0.1 Hz to 10 kHz is performed by frequency generation using function generator and optical or inductive coupler)

- other instrument functions can be also checked non‑accredited

ECG pulse simulators

ECG devices monitor heart rate on different parts of the body. ECG pulse simulators generate ECG signals at the output terminals which are then used to check the operation of ECG devices. When calibrating ECG pulse simulators, we measure the amplitude and frequency of the ECG signal. We can also calibrate other functions if available (e.g., variation of respiratory resistance, temperature measurement).

Defibrillator, defibrillator analyzer and defibrillator simulator

Defibrillators are devices that can reanimate heart with a short electrical pulse of a certain energy. Correct operation of defibrillator is checked with defibrillator analyzer. At SIQ we perform the calibration of defibrillator analyzers. Typically, we measure:

- load resistance between defibrillator electrodes (usually between sternum and apex terminals)

- voltage measurement

- energy measurement

- synchronization capability (e.g., measurement at SyncRwave output)

Another type of measuring instruments associated with defibrillators are defibrillator simulators, which are reference defibrillators that generate appropriate voltage signals that are used to verify correct operation of defibrillator analyzers. Typically, we calibrate:

- different pulse amplitudes and durations for both polarities

- accuracy of resistance measurement if the function exists

- output power/energy

- power of reference output if available

- other functional tests (e.g., sensor reading, sensor operation, etc.)

Incubators

The incubator is an independent unit for intensive care of newborns, primarily for caring ill or premature newborns. The incubator provides ideal ambient conditions (suitable temperature and humidity, prevents excessive levels of noise and light), and protects against infections and allergens. Calibration of incubators is performed at the customer’s premises. Typically, the following parameters are calibrated:

- temperature

- relative humidity

- measurement of air flow inside the incubator

- noise measurement (noise in the incubator during normal operation, ambient noise when the incubator is off, noise in the incubator when the alarm is on, noise 3-meter away from the incubator when alarm is on)

Electrosurgical units and electrosurgical analyzers

The power of electrosurgical units is measured indirectly by measuring the voltage drop and resistance of the supplied load resistance in CUT and COAG modes. We also measure the frequency of the source. For electrosurgical analyzers we measure:

- resistance between different terminals (g., patient plate – active electrode, active electrode – ground, patient plate – ground, chassis – ground, active – dispersive) for different device settings

- accuracy of current (constant voltage and different resistance settings or constant resistance and different frequencies)

- power measurement via voltage and current measurement between patient plate and active electrode for different resistance settings

Hospital installation meters

The most important parameter for hospital installation meters is leakage current which can be also calibrated at SIQ. We calibrate the following leakage currents:

- earth leakage

- enclosure leakage

- leakage between individual electrodes (dual leakage)

- patient auxiliary leakage

We also check accuracy of integrated voltmeter, insulation and earthing resistance using standard resistance decades or reference resistors. We also calibrate short-circuit currents, measuring currents, and open-circuit voltage similarly as for classic installation meters.

Fluke Prosim 8

The calibrator Prosim 8 is used to check several functions of medical devices such as ECG, respiratory resistance, temperature, pressure, etc. Typically, we calibrate:

- amplitude and frequency of the ECG signal

- variation of respiratory resistance for different outputs: LA(L)-RA(R), LL(F)-RA(R), LL(F)-LA(L)

- resistance of the outputs that simulate temperature sensors

- resistance for Cardiac output simulation

- pressure accuracy

WhaleTeq SECG 4.0, CMRR 2.0 and MECG 2.0

All three devices are calibrated according to the manufacturer’s recommendations. For CMRR 2.0 (i.e., Common Mode Rejection Ratio Tester) we calibrate the voltages, resistances, and capacitances between certain terminals of the Breakout box for different software settings. For MECG 2.0 we calibrate the amplitude and frequency of ECG signal at different output terminals of the Breakout box. For SECG 4.2 we calibrate the frequency of the ECG signal between the RA(R) and LL(F) terminals, the signal amplitude between the RA(R) and LL(F) terminals for different program settings, the voltage dividing ratio between the RA(R) and LL(F) terminals and the monitor out output, DC offset between RL/N terminal and CMRR terminal, as well as resistance and capacitance between different Breakout box terminals according to the manufacturer’s recommendations.

The calibration of other parameters is also possible for all three devices according to customer’s requirements. The customer’s Breakout box is part of the calibrated device therefore it must be provided by the customer.