Product Testing and Certification

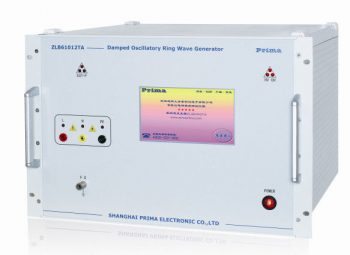

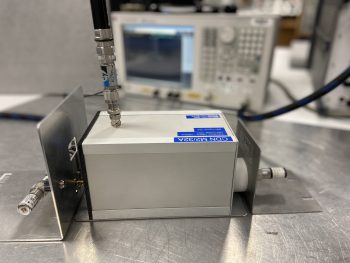

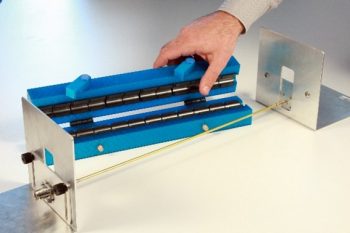

We are professional, accurate, and responsive in meeting your requirements for electromagnetic compatibility testing and certification. Our measurements, test reports, and certificates assure EMC compatibility of your product in all important markets. We provide our professional assistance already at the stage of development when we can carry out partial critical tests of individual devices. Our experts follow development trends in the field of electromagnetic compatibility of devices, and our laboratory has a modern equipment.